Best Practices for Laser Engraving Silicone

Laser engraving has gained massive popularity due to its ability to produce precise and intricate designs on a wide variety of materials. Among these, silicone has become an increasingly popular choice for engraving, owing to its versatility and flexibility in different applications, from personalized gifts to professional product designs. In this comprehensive guide, we will explore everything you need to know about laser engraving silicone, including tips, tricks, and step-by-step instructions to achieve the best results.

What is Laser Engraving on Silicone?

Before diving into the step-by–step instructions for laser engraving silicone, it’s essential to understand what laser engraving is. Laser engraving involves using a focused laser beam to create permanent designs on various materials by either vaporizing the surface or altering the material itself.

When it comes to silicone, the laser engraving process allows for precise designs that are durable and permanent. Whether you’re working with silicone rubber, silicone-coated items, or silicone-based products, the precision and detail provided by laser engraving make it an ideal choice for customization.

Why Laser Engrave Silicone?

There are several reasons why laser engraving silicone is a popular choice for both personal and commercial projects:

- Durability: Unlike other methods of marking, such as printing or stickers, laser engraving offers long-lasting results. The design won’t wear off or fade over time, ensuring that your products remain visually appealing for an extended period.

- Precision: Laser engraving allows for highly detailed and intricate designs on silicone products, which might be difficult to achieve using traditional engraving methods.

- No Chemicals: Unlike some other engraving techniques, laser engraving doesn’t require chemicals, so it’s an environmentally friendly choice.

- Variety of Products: From custom silicone wristbands and phone cases to baby products, kitchenware, and industrial items, laser engraving can be used across various silicone products to make them unique.

What You Need for Laser Engraving Silicone

Before you begin, ensure you have the right materials and equipment for the job. Here’s a list of what you’ll need:

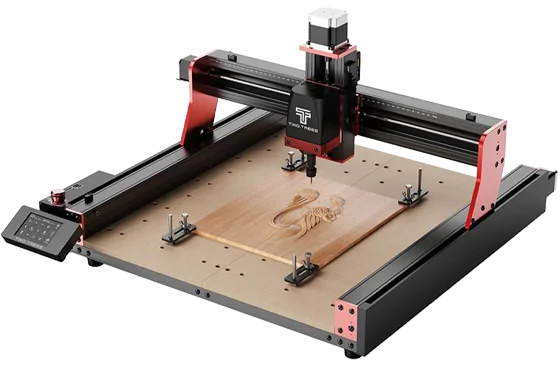

Laser Engraver

To begin with, you’ll need a reliable laser engraver. Most modern diode or CO2 lasers work well for engraving silicone. Make sure your laser has a power setting suitable for silicone, and check that it has a focusable lens for precision.

Silicone Material

Choose the silicone product you want to engrave. You can use silicone sheets, silicone-coated products, or even 3D silicone objects. The quality and thickness of the material can affect the engraving process, so be sure to select high-quality silicone.

Design Software

To create the custom designs, you’ll need design software compatible with your engraver. Common software used for laser engraving includes LightBurn, CorelDraw, or Adobe Illustrator.

Protective Gear

Safety is critical when using a laser engraver. Always wear appropriate safety glasses to protect your eyes from the intense light.

Ventilation System

Because laser engraving can produce smoke, fumes, and particles, having an effective ventilation system is important. A proper exhaust fan or air filtration system will help keep the engraving process safe and clean.

Step-by-Step Instructions for Laser Engraving Silicone

Step 1: Prepare the Silicone Material

Before starting the laser engraving process, make sure your silicone material is clean and free from dust or debris. If necessary, wipe the surface with a soft cloth and mild soap solution.

Step 2: Create or Upload Your Design

Next, open your design software and create or upload the design you wish to engrave onto the silicone. It’s important to consider the resolution and size of the design to make sure it fits the engraving area.

- Tip: Keep your designs simple, as intricate designs may not show up well on silicone, especially if it’s too soft or thick.

Step 3: Set Up the Laser Engraver

Now, place your silicone material onto the laser engraving bed. Ensure that it’s securely positioned, so it won’t shift during the engraving process. Next, adjust the settings on your laser engraver:

- Laser Power: Set the appropriate power for silicone engraving. Typically, a power level between 30-40% should suffice, but it may vary based on the thickness of the material.

- Speed: Adjust the speed setting for optimal engraving. Slower speeds typically result in more detailed and deeper engravings, but too slow might lead to scorching or burns. A moderate speed of 300-400mm/s is typically a good starting point for silicone.

- Frequency: Set the frequency according to the engraver’s specifications. Higher frequencies allow for finer details, while lower frequencies can result in deeper engraving.

Step 4: Test Engraving

Before you proceed with the final engraving, it’s always wise to run a test engraving. This will allow you to check the settings, make sure the laser focus is correct, and observe how the silicone reacts.

During the test, keep an eye on the engraving quality. If the result is too light, adjust the power or speed. If the engraving is too deep, reduce the power or speed settings accordingly.

Step 5: Begin the Engraving Process

Once satisfied with your test engraving, go ahead and start the main engraving process. Keep an eye on the process, especially during the first few minutes, to ensure everything is running smoothly. If the laser begins to overheat or create excessive fumes, stop the machine immediately and check for any issues.

Step 6: Clean Up and Inspect the Result

After the engraving is complete, let the silicone material cool down if necessary. Carefully remove the product from the engraving bed. Inspect the design to ensure the quality meets your expectations.

If necessary, clean the surface using a cloth to remove any excess soot or particles left from the engraving process.

Troubleshooting Tips

Despite careful preparation, issues can sometimes arise during the engraving process. Here are a few common problems and their solutions:

- Faded Design: If the design appears too faint, you might need to increase the laser power or decrease the engraving speed for better contrast.

- Burn Marks: If you notice burn marks around the design, lower the laser power or increase the speed to reduce heat buildup.

- Blurry Design: If the design lacks clarity, check the focus of the laser. It’s essential that the laser is focused properly for the best precision.

Why Choose DhuniKart?

DhuniKart, we are passionate about providing quality tools and products for all your engraving needs. Whether you’re just starting or a seasoned professional, we are committed to offering laser engravers that guarantee high-quality and precise results. Our products, such as laser engravers for silicone, are carefully selected to meet the demands of every engraver.

Our expert support team is always here to guide you through any challenges you may face with your engraving projects. By choosing DhuniKart, you are not only investing in superior laser engravers but also in exceptional customer service and ongoing support.

Conclusion

Laser Engraving Silicone is an excellent method for creating precise, detailed, and durable designs on silicone products. By following these step-by-step instructions for laser engraving silicone, you can achieve professional results in your engraving projects. Whether you’re working on personalized silicone products, gifts, or industrial components, laser engraving silicone offers unmatched quality and versatility.

FAQ

1. Can I laser engrave silicone at home?

Yes, you can laser engrave silicone at home with the right laser engraver and proper settings.

2. How do I choose the right laser engraver for silicone?

Look for a laser engraver with adjustable power settings and precision for engraving silicone.

3. What settings should I use for laser engraving silicone?

Start with 30-40% laser power and moderate speed, then adjust as needed for the silicone type.

4. Can I laser engrave silicone-coated items?

Yes, you can, but ensure the settings are adjusted based on the coating thickness.

5. How do I prevent burning or fading when engraving silicone?

Adjust the laser power and engraving speed to avoid burning or fading on silicone.

For more information about these, call us at +91 8866664329 or mail us at: support@dhunikart.in.