Have you ever built something with your own hands and felt that quiet pride that only makers understand? That feeling is driving a new wave of DIY creators, product designers, and small workshop owners across India. They want tools that work, tools that stay reliable, and tools that help ideas move from screen to real life. That’s where Two Trees equipment steps in. From home projects to serious prototyping and small-scale production, these machines fit into real workflows. This guide explains the real, practical uses of Two Trees equipment, how people work with it every day, and why so many creators keep checking the Two Trees Archives when planning their next upgrade.

What Is Two Trees and Why People Trust It

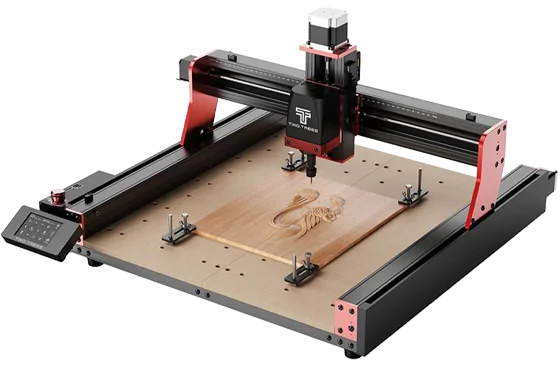

Two Trees is a well-known name in the desktop fabrication space. The brand focuses on machines that support 3D printing, laser engraving, and CNC-style creative work. These tools are made for people who want control, accuracy, and repeatable results without needing factory-scale setups. When users browse the Two Trees Archives, they usually look for machines that balance performance with size and cost. That balance is what makes these tools popular among hobby users, design studios, schools, and small businesses.

Why Desktop Fabrication Matters Today

Ideas move fast today. Waiting weeks for a prototype slows everything down. With tools from Two Trees, creators can design, test, change, and build again in the same week, sometimes on the same day. This speed is not only for engineers. Artists, crafters, and small business owners use these machines to create real products. The Two Trees Archives show how wide this usage has become across different fields.

DIY Projects That Feel Professional

Home Decor and Custom Gifts

Many DIY users start with simple projects like wall art, nameplates, lamp covers, and custom gift items. Two Trees machines help cut and engrave wood, acrylic, leather, and similar materials with clean edges and fine detail. This changes how home projects look. They no longer feel handmade in a rough way. They look finished and ready to sell.

Hobby Models and Creative Builds

Model makers and hobby builders use Two Trees equipment to cut parts, engrave details, and build accurate structures. This saves time and improves accuracy compared to hand tools. People often share such projects in the Two Trees Archives, which helps new users understand what is possible with these machines.

Prototyping That Saves Time and Money

Product Design and Testing

Designers use Two Trees machines to create early versions of products. This could be a phone stand, a small tool, a custom enclosure, or a display unit. Instead of sending files to outside workshops, they build and test in-house. This short feedback loop is one of the biggest reasons small teams invest in tools from Two Trees.

Fit, Form, and Function Checks

A prototype is not only about how something looks. It is also about how it fits and works. With desktop machines, designers can check size, grip, assembly, and basic function before spending money on mass production tools. Many such stories appear in the Two Trees Archives, shared by startups and independent makers.

Small Manufacturing That Feels In Control

Short Run Production

Small businesses often need 10, 50, or 200 pieces, not 10,000. Two Trees machines support this kind of work very well. They can cut, engrave, or prepare parts in small batches with consistent quality. This is perfect for custom signs, branded items, craft products, and personalized goods.

Customization as a Business Model

Customers today like products with names, dates, or special messages. Two Trees equipment allows small workshops to offer this service without slowing down the whole process.

This is one reason why people searching the Two Trees Archives often come from gift shops, print shops, and small craft brands.

Real Materials People Work With

Most Two Trees machines support materials like wood, MDF, acrylic, leather, rubber sheets, and some coated surfaces. In 3D printing setups, users also work with common filaments like PLA and similar materials. This material range covers a huge part of DIY, prototyping, and small manufacturing needs.

A Look at Typical Workflows

A normal workflow looks simply. Design starts on a computer. The file goes to the machine. The machine cuts, engraves, or prints. The user cleans the part and assembles or finishes it. What makes Two Trees equipment popular is that this workflow stays smooth and predictable once the machine is set up correctly.

Learning Curve and Daily Use

Most users say the first few days involve learning and testing. After that, work becomes routine. That is where productivity starts to show. Communities and examples found in the Two Trees Archives help new users avoid common mistakes and move faster toward stable results.

Why These Machines Fit Small Spaces

Not everyone has a big workshop. Many creators work from home, small studios, or shared spaces. Two Trees machines are designed to fit on tables or small stands. This makes them practical for people who want to start small and grow step by step.

Quality, Consistency, and Repeatability

For business use, consistency matters. Customers expect the same result every time. Two Trees equipment supports repeatable jobs once settings are saved and tested. This is why many small sellers move from manual tools to these machines after checking real examples in the Two Trees Archives.

Common Mistakes New Users Should Avoid

Some users try to rush setup. Others skip testing and go straight to final material. This often leads to waste and frustration. Experienced users of Two Trees machines usually suggest slow, careful setup and small test runs before full jobs.

How Dhunikart Supports Two Trees Users

Dhunikart works with creators, small businesses, and institutions that want reliable desktop fabrication tools. The team does not just sell machines. It helps users understand what fits their work.

Dhunikart also follows the developments and updates shown in the Two Trees Archives, which helps customers get current and relevant options. Many users come back to Dhunikart when they want to expand or upgrade their setup. Dhunikart focuses on clear advice, proper product matching, and long-term support. That approach helps users avoid costly mistakes and get real value from Two Trees equipment.

Where Two Trees Equipment Makes the Biggest Difference

- In classrooms and training centres for practical learning

- In design studios for fast prototyping

- In home workshops for creative projects

- In small businesses for custom product work

- In maker spaces for shared tools and learning

These use cases keep growing, and that growth is well documented across the Two Trees Archives.

Why Choose Us

Dhunikart believes that tools should match real work, not just look good on paper. The team spends time understanding what each customer wants to build and then suggests the right Two Trees solution. Dhunikart focuses on honest guidance, reliable supply, and long-term support. Every customer gets help not only at the time of purchase but also during setup and daily use. This approach has helped many creators, small businesses, and educators turn ideas into real products with confidence and steady results.

Conclusion

Two Trees equipment has changed how people approach DIY, prototyping, and small manufacturing. It brings professional-level control into small spaces and small budgets. From creative home projects to serious product development and short-run production, these machines support real work every day. The growing library of examples in the Two Trees Archives shows how wide and practical these uses have become. With the right guidance and setup, these tools can become the core of a creative or business workflow. Dhunikart continues to help users take this step with clarity and confidence.

Want to explore real uses of Two Trees equipment for your projects or business? Call +91 8866664329 or email support@dhunikart.in and get clear guidance based on your actual needs today.

Key Takeaways

- Two Trees equipment fits DIY, prototyping, and small manufacturing work.

- The Two Trees Archives show many real and practical use cases.

- These machines save time by keeping design and production in one place.

- Small workshops and home studios benefit the most from this setup.

- Dhunikart helps users choose and use the right tools with proper support.

FAQs

What kind of users benefit most from Two Trees equipment?

DIY creators, product designers, educators, and small business owners benefit the most from Two Trees machines because they need flexible and compact tools.

Can Two Trees machines handle small business production work?

Yes, many users run short batch and customized product jobs using Two Trees equipment with stable and repeatable results.

Where can I see examples of real projects?

You can explore many real project ideas and setups in the Two Trees Archives, which show how different users apply these machines.

Is the learning process difficult for beginners?

Most beginners learn the basics within a few days. Community guides and support make the process smoother.

Why should I buy Two Trees equipment from Dhunikart?

Dhunikart offers honest advice, proper product matching, and long-term support, which helps you get real value from your Two Trees setup.