What is a CO2 Laser Engraver and Where to Use It

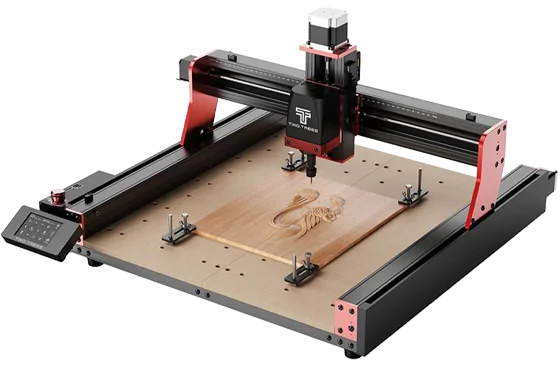

A CO2 laser engraver is a high-precision machine that uses a carbon dioxide gas laser to cut, engrave, or mark various non-metal materials. It produces a powerful, invisible laser beam that interacts with the surface of the material to either vaporize, melt, or burn it, creating sharp and detailed patterns. This type of laser engraver is highly effective on wood, acrylic, leather, rubber, fabric, glass, and certain types of plastics. It is not typically used for metal unless a special marking spray is applied.

Thanks to its clean and accurate output, the CO2 laser engraver is widely used in many creative and commercial industries. It’s a go-to tool in signage production, craft making, fashion accessory design, packaging, and personalized gifting. Whether you’re a small business owner designing customized merchandise or a hobbyist creating home décor or art pieces, this machine can deliver professional-quality results with speed and ease. Its user-friendly features, combined with its versatility, make it a valuable investment for anyone looking to produce detailed and beautiful work on non-metal surfaces.

Importance of Understanding Its Capabilities and Limitations

Before investing in a CO2 laser engraver, it is essential to understand what it can and cannot do. While it excels at working with non-metal materials, it is not effective on bare metal without the use of additional marking sprays. Knowing its strengths helps you make better buying decisions and prevents damage or poor results. It also ensures you get the best use of the machine while avoiding potential safety risks.

How a CO2 Laser Engraver Works

Technology Behind the CO2 Laser Engraver: A CO2 laser engraver uses a gas mixture (mainly carbon dioxide) that is electrically stimulated to produce a laser beam. This beam is then directed by mirrors and focused through a lens onto the surface of the material. The energy from the laser heats up and vaporizes the surface in a precise and controlled manner, leaving behind a mark or cutting through the material completely.

How the Engraving Process Takes Place: The engraving process begins when the laser beam hits the material. The intensity and speed of the laser can be adjusted depending on the material type and thickness. For engraving, the laser removes only a thin layer, leaving a clear design, logo, or text. To cut, the laser beam goes slowly and with increased power through the material. The whole process is contactless, which reduces wear and tear while increasing precision.

Applications of CO2 Laser Engravers

CO2 laser engravers are used in many industries because of their ability to cut and engrave a wide range of materials with great accuracy. In the signage industry, they are popular for making signboards, nameplates, and acrylic displays with sharp, clean edges. In the textile and leather industries, these machines are used to create patterns, engrave logos, and cut fabric or leather into detailed shapes for clothing, bags, and accessories. The packaging industry also relies on CO2 laser engravers to cut cardboard boxes, create custom labels, and engrave brand names or product details on packaging materials. In education, teachers and students use them to create classroom models, DIY kits, and project displays. Architects and designers use CO2 lasers for making scale models and design prototypes with fine details. From small businesses to large-scale manufacturing, CO2 laser engravers offer speed, flexibility, and a high-quality finish, making them an essential tool across many creative and industrial fields.

Examples of Products That Can Be Created with CO2 Laser Engraving:

- Personalized gifts like wooden photo frames and keychains

- Acrylic signs and logos

- Leather wallets, belts, and handbags

- Glass awards and trophies

- Decorative items like lamp covers and wall art

- Rubber stamps

- Packaging boxes with detailed cut-outs or designs

- Clothing labels and fabric tags

Factors to Consider When Buying a CO2 Laser Engraver

Power and Wattage Options: Power is one of several essential features to examine. Lower wattage (40W-60W) is suitable for light materials like paper, leather, and thin wood. Medium wattage (60W-100W) can handle thicker wood, acrylic, and rubber. High wattage (100W or above) is useful for cutting quickly and through materials that are thicker. Choose the power based on your material types and volume of work.

Bed Size and Cutting Area: The bed size determines the maximum size of the material you can work with. If you’re doing large designs or batch processing, choose a machine with a larger bed. Smaller machines are fine for hobby work or limited-space workshops. A common bed size for medium use is 600x400mm.

Software and Compatibility Features: Check if the machine includes user-friendly software for design and control. It should support common file formats like JPG, PNG, SVG, and DXF. Also, ensure compatibility with your operating system (Windows, Mac, or Linux). Some machines also allow Wi-Fi or USB connectivity for easier data transfer.

Safety precautions while using a CO2 laser engraver

Proper Ventilation and Filtration Systems: Laser engraving produces smoke and fumes, especially when working with wood or acrylic. A good ventilation or air filtration system is necessary to keep the workspace safe. It also protects your lungs from harmful particles and extends the life of the machine.

Protective Gear and Procedures to Follow: Always wear safety glasses when the machine is running. Avoid looking directly at the laser beam. Always make sure that the space is free of burning items. Never leave the equipment unattended when it is running. Having a fire extinguisher nearby is also a smart safety measure.

Maintenance Tips for Keeping a CO2 Laser Engraver in Optimal Condition

Cleaning and Calibration Instructions: Regular maintenance keeps your machine running smoothly. Clean the mirrors and lenses weekly to avoid loss of beam quality. Wipe the bed area to remove dust and debris. Calibrate the focus lens regularly for accurate engraving. Lubricate all moving components as directed by the manufacturer.

Troubleshooting Common Issues: If the machine is not cutting properly, check for dirty lenses or low power settings. Misalignment of mirrors can also cause engraving errors. Strange noises or sudden stops may point to loose parts or software errors. Following the user manual for troubleshooting can solve most issues quickly.

Where to Buy a CO2 Laser Engraver in India

Finding the best site to buy a CO2 laser engraver in India is just as important as choosing the machine itself. A trusted seller ensures that you get genuine products, expert advice, and proper after-sales support. If you’re planning to buy a CO2 laser engraver in India, Dhunikart is one of the best platforms to consider. They are an authorized dealer and distributor of well-known brands like Xtool, AlgoLaser, Sculpfun, and Atomstack. This means you’ll receive only original, brand-certified machines backed by warranty and service. Whether you’re new to laser engraving or expanding your business, Dhunikart offers expert guidance during the selection process, helping you choose the right machine based on your needs. You also benefit from customer support that includes installation help, troubleshooting, and timely maintenance services. Shopping from a trusted platform like this gives you peace of mind and ensures long-term satisfaction. For quality products and dependable service, Dhunikart is one of the best options for buying CO2 laser engravers in India.

Conclusion

CO2 laser engravers are versatile machines that bring speed, accuracy, and creativity to a wide range of industries. From personalized gifts to industrial signage, their applications are endless. Understanding how they work, what materials they can handle, and how to maintain them can help you get the most out of your investment. Whether you’re a small business or a creative enthusiast, exploring the world of CO2 laser engraving opens up many possibilities.

Ready to take your creativity or business to the next level with a reliable CO2 laser engraver? Get expert support, genuine machines, and top-tier service all in one place. Call us at +91 88666 64329 or Email support@dhunikart.in to speak with our team today and find the perfect laser engraver for your needs!

FAQ

1. What materials can a CO2 laser engraver cut or engrave?

CO2 laser engravers can cut and engrave wood, acrylic, leather, fabric, rubber, paper, and some plastics. They’re not ideal for bare metals unless used with marking spray.

2. Can you use a CO2 laser engraver in metal?

Standard CO2 lasers can’t engrave directly on bare metal. However, with a metal marking spray or paste, you can achieve surface marking on certain types of metals.

3. Is a CO2 laser engraver safe to use at home?

Yes, it’s safe when used correctly. Always follow safety guidelines, wear protective glasses, and ensure proper ventilation to avoid fumes during operation.

4. What industries use CO2 laser engravers?

Industries like signage, fashion, crafts, packaging, architecture, and education use CO2 laser engravers for cutting, engraving, and prototyping various materials.

5. How much maintenance does a CO2 laser engraver need?

Regular cleaning of lenses, mirrors, and filters is required. Also, keep the machine calibrated and check for wear on moving parts to ensure top performance.

6. What power level should I choose for a CO2 laser engraver?

For basic engraving, 40W–60W is sufficient. If you’re doing deeper cuts or handling thicker materials, 80W–150W machines offer better results.

7. What software is compatible with CO2 laser engravers?

Most machines support software like LightBurn, RDWorks, or LaserGRBL. Compatibility depends on your engraver’s controller and the type of projects you’re doing.

8. Do CO2 laser engravers need ventilation?

Yes, proper ventilation or an exhaust system is essential to remove smoke and fumes generated during the engraving process, especially when working indoors.

9. How long does a CO2 laser tube last?

A typical CO2 laser tube lasts around 1,000 to 2,000 hours. Lifespan depends on usage, cooling, and how well the machine is maintained.

10. Where can I buy a CO2 laser engraver in India?

You can buy CO2 laser engravers from trusted platforms like Dhunikart, offering genuine brands, expert support, and after-sales service across India.